Sustainability Report 2020

About this report

El-Kretsen’s fourth sustainability report

It refers to the performance in 2020 of the company as a whole and has been produced in accordance with Swedish accounting law. Since last year we have digitalised our accounting routines and our reporting can now be found in a dedicated accounting section focusing solely on our own business. Being able to correctly determine where our influence begins and ends is always a challenge. Take, for example, the metals and various components that make up the electronic products we handle. For these areas we have refrained from reporting data and focus instead on listing the processes we use and the evidence we get that we are making a positive difference.

A Message from the CEO

2020: A year of challenges and highlights

2020 will go down in history as the year the pandemic paralysed our world. Things we used to take for granted, like travelling and socialising, can no longer be done at a whim. Like everybody else, we have spent a lot of energy identifying and discussing uncertainties. So far, I’d say that El-Kretsen’s core business has not been deeply affected. Electric and electronic products are still being sold and we are still doing collections. However, our interaction with the rest of the world is greatly reduced. While digital meetings have become all the rage, paradoxically they are best suited for doing local and regional business.

Last summer, the Swedish government published the report “Circular Economy – A Strategy For Sweden’s Transition”. To have reached a point where sustainability is allowed to bridge and link two areas that have traditionally been kept separate, namely finance and the environment, is a major milestone. Political instruments have been discussed in Sweden as well as in the rest of the world, as a means of reaching a higher degree of circularity. At El-Kretsen we are getting more questions about what can be done to return more materials to the manufacturing process or to somehow reuse the products we collect (or at least parts of them). Another question is how we can share our knowledge of collection and recycling, particularly with other countries. The amount of WEEE is increasing on a global level, but seeing the reality behind the statistics is not always easy. Keeping Sweden’s statistics separate from global statistics is a challenge, as is communicating that while reuse and export can be positive moves, they nevertheless have an adverse effect on the national recycling statistics. In the end, the solution that results in the greatest environmental benefit is the one to choose. This is our way of bringing the concept of circular economy into the real world.

Talking of real progress, some good news is that in 2020 the facility that receives a lot of the metals resulting from WEEE in Sweden, Rönnskärsverken, has built a leaching plant. This means that a lot of what used to escape as residual waste can now be processed one more time. This enables more resources to be reused which in turn reduces the amount of landfill.

In previous years, articles, reports and statistics were all merged to form the sustainability report. However, one of our fears has been that these reports have not reached as many readers as we would have liked, and this was confirmed in our 2020 customer survey. The feedback was that those who did read the sustainability report appreciated it and found the contents useful. Strengthened by this information we have now decided to single out and reprint some of the reports and articles on our new website: Sustainability Library. Do you want to know more about the collection and recycling processes? Are you curious about why some materials are recovered while others are not? Do you want to explore the statistics for the entire country or relating to a certain municipality? Find the answers to all this and more on our brand new site. And hey! Please spread the word to others!

About El-Kretsen

Circularity in practice

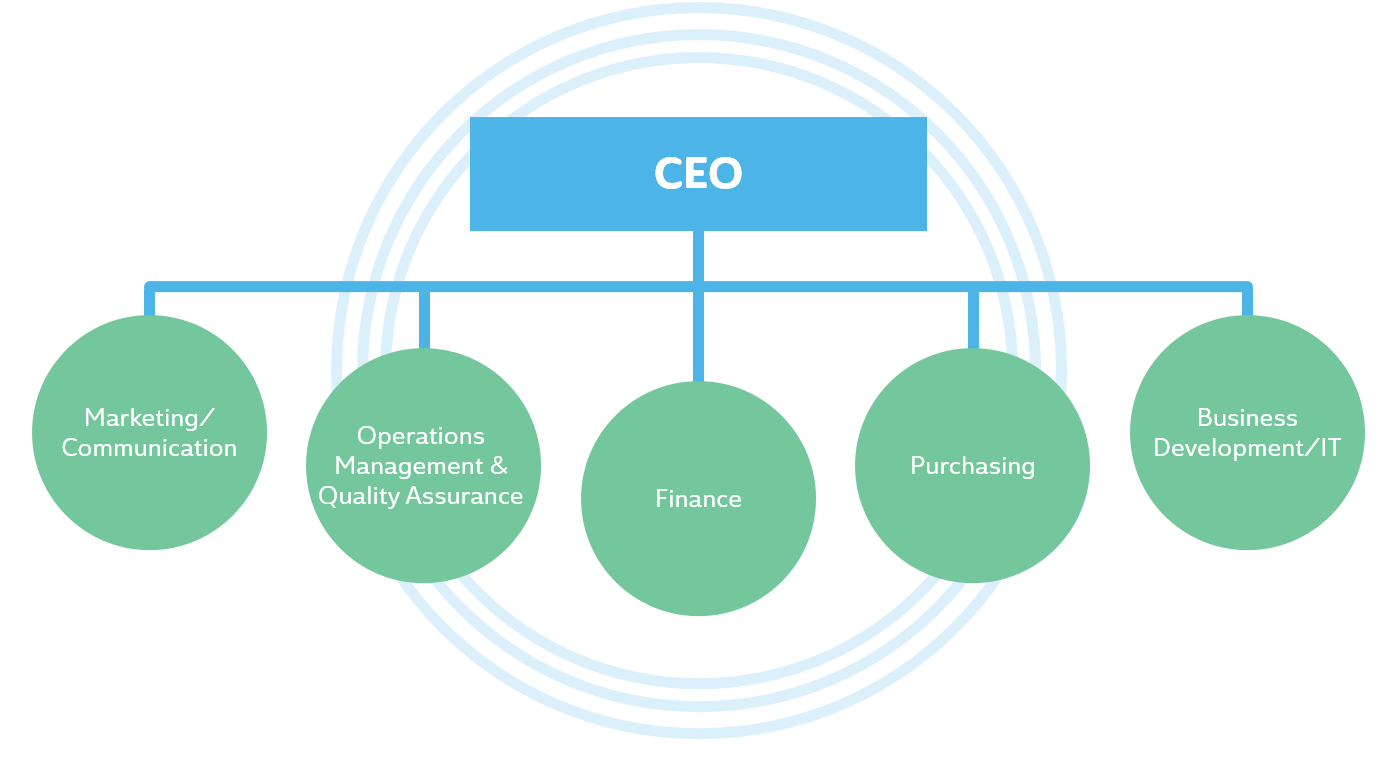

El-Kretsen, one of Sweden’s nationally approved collection system for WEEE and batteries, is a non-profit organisation owned by 21 trade organisations. It was set up in 2001 when the producer responsibility legislation came into force to enable joint administration, handling and collection of the products concerned. The collection, transportation and pre-treatment operations are carried out by a network of external partners. Despite dealing with large volumes all over Sweden, El-Kretsen only has 14 employees. The company is based in Stockholm in premises we share with Näringspunkten, a network of trade associations including many of El-Kretsen’s owners.

- Marketing/Communications – Responsible for El-Kretsen’s website, the production of information and publicity materials for customers, as well as for the customer support that services affiliated producers.

- Operations Management & Quality Assurance – Responsible for collection and logistics as well as for customer support servicing municipalities, collection points, transportation companies and pre-treatment companies

- Finance – Responsible for budget work, invoices and external questions on financial matters.

- Purchasing – Responsible for the procurement of services and purchasing of materials.

- Business Development/IT – Responsible for El-Kretsen’s IT system, its analytical plant and for external research projects.

In 2020, El-Kretsen employed 14 people (5 men and 9 women). Their contracts include a certain degree of flexi-time, regular health check-ups and further training opportunities. El-Kretsen has established a systematic Health and Safety management system based on Swedish labour legislation and the standards ISO 14001 and ISO 9001. We apply an Equal Opportunities plan which continually canvases and measures the employees’ view of El-Kretsen as a workplace. This Equal Opportunities plan includes policies on gender-neutral wage setting, anti-harassment, etc. In 2020, no work injuries were reported. The total number of hours of paid sick leave amounted to 645, of which women accounted for 248 and men for 397.

2020 in brief

Rise in sales and collection

2020 started like any other year, but as we moved from January into February and March, the concern over what was to come rose considerably. As of April, “working from home” became the new norm for those of us who could. But while the pandemic has affected society on many different levels, it’s very clear that it hasn’t affected the sales of electronic products. In the Home Electronics product segment, total sales value rose by 12 per cent compared with 2019, where the sale of TVs was in a league of its own and went up by as much as 29 per cent. This rise in sales may be linked to the WEEE collected. During the first phase of the pandemic, there was a marked increase in the amount of WEEE collected. One conclusion we drew from this was that people now working from home had taken time to clear out their cupboards and closets and make the trip to a recycling station. It resembled the peak in WEEE returned which we normally see in the summer period – in 2020, the peak just came earlier.

All in all, the amount of WEEE collected increased by 5.5 per cent in weight. The Refrigerators and Freezers fraction increased the most, by 14 per cent. On the whole, 156,000 tonnes, or an estimated 67 million electric and electronic products, were handled by El-Kretsen’s collection system in 2020. But regardless of how enormous this figure seems, it corresponds to no more than 0.3 per cent of the total global influx of WEEE. At El-Kretsen, we are continuously working on future recycling processes and the knowledge we obtain along the way may also be useful to other parties. This means that there is scope for us, after all, to have a positive influence also on the remaining 99.7 per cent.

Producer Responsibility

A growing need for circularity

WEEE is the fastest-growing waste category, last year accounting for around 55 million tonnes of waste globally. This is an increase of 10 million tonnes over the last 5 years, and the trend continues unabated. By 2030, the total global amount of WEEE is forecast to amount to some 75 million tonnes. Only 20 per cent of all this WEEE is treated in official recycling systems. We can’t be certain of what happens to the rest, but we can be pretty sure that it isn’t dealt with in a sustainable manner. For this reason, it is imperative that we promote both secure and more circular systems for handling WEEE.

The growing amount of WEEE is a result of ongoing technological developments and a growing global population where more and more people can afford to buy electronic products. While this is fundamentally positive, not all planet Earth’s resources are renewable and its ecological systems are unable to cope with the untreated waste that just gets dumped. We need to look after our natural resources much more carefully, and recycling is a far less energy-intense way of obtaining raw materials than extracting virgin natural resources. This in itself is enough to make circular systems the natural and obvious goal.

At the same time, a shift to circular systems requires an enormous effort in relation to the current setup – and here, Sweden is no exception. Despite the fact that El-Kretsen (in organisational terms) and Sweden (in national terms) have come a long way when it comes to recycling, we still have some distance left to go. As of yet, none of the materials that go into electronic products are recycled to 100 per cent, but our goal is to get there. And we, the collection system, share this goal with EEE producers who have equally high ambitions. Right now, many studies are looking into things like how metals are used, what environmental impact they have, how they can be recycled and/or replaced by other materials, and much more.

Sustainability Management

Quality measurement

El-Kretsen’s mission statement is based on producer responsibility and recycling. Relying on safe processes and making sure our work contributes to a reduced carbon footprint are two core values. We implement ISO 14001 and 9001 to make sure we highlight risks and possibilities as well as issues and activities that are important with regard to the environment and quality assurance.

El-Kretsen’s general business policy was last revised at the end of 2019 and has remained in force since then. It forms the basis for the decisions we make and you can also find it on our website: El-Kretsen is a service company that manages the collection and recycling of batteries and electric and electronic products for the Swedish business sector. El-Kretsen should be known for its high degree of competence, service-mindedness, responsibility and flexibility and for its awareness of what impacts on quality and our natural and working environments. We persistently and systematically work on engaging competent colleagues who strive always to use the most environmentally-friendly and economically viable solutions to treat the waste we collect. All our actions are characterised by our commitment to maintain high social, environmental and ethical standards with respect to all our partners. El-Kretsen prevents pollution and lives up to the legislation present in our society and the demands placed upon us by our partners.

To ensure that we deal with the waste in the best and most sustainable manner possible, we require all our partners to be certified by either of the two European standards organisations Cenelec or Weelabex. In previous years, several different certification bodies were accepted in different countries and by different organisations, but these days, Europe and most collection systems have agreed to adhere to either Cenelec or Weelabex. El-Kretsen has played a prominent part in this development, with the result that Sweden has a presence in both (in the shape of a representative and an accountant respectively). At El-Kretsen we find it very valuable having close expert associates on these complex matters that often border on adjacent areas like, for example, the legislation on chemicals. The flows of materials are reported in the common reporting tool Reptool.

In addition to this, El-Kretsen also adheres to the producer legislation requirements for collection systems. The authority that approves and performs audits to ensure that El-Kretsen meets the requirements stipulated in the Ordinance is the Swedish Environmental Protection Agency (SEPA).

Our stakeholders

To compare apples with apples

Central to El-Kretsen and our partners is agreeing on the terminology used in our field. It is important to know what we mean when we talk about “recycling”. Is it “raw materials recycling” (when aluminium, for example, is recycled to such a degree of purity that it can re-enter the market as a raw material), “reuse recycling” (referring to waste that in its existing form is reused in a new context, like concrete waste that is crushed and used to cover landfills) or “waste-to-energy recycling” (when waste is incinerated to produce energy or district heating)?” When we make comparisons between Sweden and other countries, we want the comparison to be made on equal grounds. Even if the directive that governs the producer legislation is applicable in all EU countries, there is still scope for individual interpretation. This is why El-Kretsen maintains a close dialogue with SEPA and many other stakeholders to cover such issues.

Elreturrådet is a consultation body that monitors the efficiency of the waste collection system and discusses how it can be improved. Elreturrådet is made up of representatives from different municipalities and regions in Sweden and from the Swedish Waste Management Association, the municipalities’ representative organisation. In 2020, a lot of the discussions have focused on the expectations of the different parties. The agreements between El-Kretsen and Sweden’s municipalities are coming up for renegotiation in 2021, and in view of that, an opportunity to pinpoint and discuss various angles and aspects is very valuable. Moreover, Elreturrådet has focused on battery collection and how we can ensure that the collecting and recycling of batteries continues to be of a high quality.

In the autumn of 2020, a survey was sent out to those in charge of producer declarations. This survey covered topics like how they regard El-Kretsen’s sustainability effort, whether they are satisfied or lack information of any kind and if they feel our customer support provides a good service (such as responding reasonably quickly and successfully dealing with the customers’ issues). Some of the questions feature regularly in our surveys and some were new.

When asked if El-Kretsen achieves its business objective – to offer a simple, cost-efficient and environmentally-friendly solution to deal with producer responsibility – 59 per cent reply that they “strongly agree” and 26 per cent that they “more or less agree”. This is a distinct improvement. The survey indicates that our users are generally positive about the day-to-day management, the information on how to make a producer declaration, etc. Of those who responded to the survey, only 33 per cent said that they had read the Sustainability Report – but as many as 76 per cent of those who had read it found the information useful. By digitalising the contents and making more of our information on sustainability available online instead of turning it into a report, we hope to reach more readers.

Logistics

Towards sustainable transports

The largest aspect of environmental impact which El-Kretsen is able to influence is transportation. The transportation of WEEE and batteries from the collection points to the pre-treatment facilities is currently handled by 15 different transport companies. These transport services have been commissioned by procurement. In addition to comparing cost and quality, we require tender applicants to provide an environmental report which has to include information on distance covered, type of fuel used and vehicle category rating according to the Euro emissions standard. We meet up with all our transporters every year to ensure that their internal environmental work is progressing according to plan and to discuss the quality of our collaboration and what could be improved in order to further optimise transport solutions. These discussions have amongst other things resulted in us adding new services in our apps and systems.

El-Kretsen wants to see 70 per cent of transport using renewable fuels. This target has not yet been met. Nor is it likely to be met in the near future, as the supply of renewable fuels has proven to be a major limiting factor. In 2020, around 44 per cent of the transport used renewable fuels.

Another important way of minimising the adverse climate impact is driving as few miles per tonne as possible. To achieve this, routes are carefully planned and lorries are loaded as full as possible. Actively striving to increase the collection containers’ fill rate and taking full advantage of the lorries’ capacity has positive results on the balance sheet as well as the environment.

In 2020, we drove a total of approximately 4,500,000 km. This corresponds to around 1,900,000 litres of fuel or 3,300 tonnes of carbon dioxide equivalent (CO2e).

To compare, the emissions resulting from mining fresh materials instead of recycling existing materials would vastly exceed the figures above. Take aluminium, for example, where the virgin extraction and primary aluminium production requires almost 98 per cent more energy than producing aluminium through recycling. Another example is the CO2e from old refrigerators, which we capture and save by handling these fridges separately in a specialised closed system. Today, greenhouse gases from refrigerants used in capacitors and insulation found in refrigerating appliances are handled in completely closed systems. If they were released instead, they would generate 1.2 million tonnes of CO2e instead of the approximately 3,300 tonnes of CO2e generated annually by our transporters.

Risks and Top Priority

To contribute without harm

Our biggest contribution to a sustainable development is our core operation. The more materials El-Kretsen recovers, the greater the environmental gain as it reduces the pressure to mine new raw materials and the risk of hazardous substances leaking out into nature. At the same time, collecting and recycling waste involves being exposed to a number of risks. To pursue the end goal and to identify and handle a number of risks not encountered anywhere else, we use an ISO-based process, where both risks and possibilities are appraised based on influence, likelihood and resourcefulness.

Indirect risks

Indirect risks include electronics that are not properly recycled. These products are either not recycled at all, or processed in a manner that is hazardous to people’s health and/or the environment. It is vital that all products containing metals and other components have more than one life cycle. Equally vital is a recycling process free from unnecessary risks. The fact that the informal sector handles a large part of the world’s WEEE comes with a major and obvious risk that this waste is not processed with a focus on sustainability, but to produce the highest possible profit.

Direct risks

The direct risks relate to our own operations. At El-Kretsen, we work with some fifteen different transport companies. Insufficient fill rates, old fleets and aggressive driving styles all contribute to unnecessarily high levels of CO2e emissions, so we work hard to make sure these are avoided. As we handle hazardous waste, another direct risk is that of accidents involving staff or the environment. Most of our collecting is done in co-operation with Swedish municipalities and their recycling centres. There are different containers for WEEE and the re-sorting is handled by El-Kretsen’s sub-contractors. This handling poses direct risks to the natural environment. Some measures are now regulated by special legislation, such as the requirement for weather proofing at collection points or the requirement for special containers for transporting batteries. Precise regulations lessen the risks, but they do not affect the scope for human error, for example as a result of carelessness and ignorance in conjunction with loading and transporting WEEE.

This also applies to personal injuries. These can be direct accidents like falling, crushing or transport-related accidents, and indirect harm can be caused through contamination or inhaling hazardous substances such as asbestos or mercury. Finally, corruption and unethical business methods always constitute a threat to any business operation, ours included.

Working for the overall goal as well as identifying and managing unique risks is done using a structure according to ISO standards. The risks described above are listed and valued on the basis of probability, consequence and El-Kretsen’s disposal of the risk. Identified opportunities are valued in the same way.

For 2020, the following detailed risks have been identified with significant risk figures:

- Risk of substandard decontamination and/or lack of traceability downstream of procured subcontractors. Action: audit by external certified public accountant. By 2020, all suppliers have been checked.

- Risk of not reaching national collection and recycling targets for certain categories. Action: Monitoring, follow-up and dialogue with the authority for consensus on which concepts and techniques are classified as material recycling. Internal project initiated to increase the material recycling rate in certain categories.

- Risk of high vulnerability in the event that key competence should disappear, if staff quit or become long-term ill. Action: Project initiated to identify how sensitive projects within each process are documented.

- Risk of rule changes that do not lead to increased environmental benefits. Action: That El-Kretsen clarifies what is the basis for statistics, for example how technology changes can affect collected kilos and recycling levels. At the same time, El-Kretsen is proactive and looks at opportunities for how different materials can be recycled even better.

Anti-corruption

Our procurement processes include a requirement for international standards that uphold a clear position on anti-corruption as well as methods for preventing corruption. We use the guidelines set by CECED (the European Committee of Manufacturers of Domestic Equipment). Their policy covers a vast array of environmental, social, ethical and health-related issues, two of which are corruption and human rights. The CECED policy is a well-established and well-prepared model for placing specific demands on European cooperation projects.

We have identified El-Kretsen as a possible conveyor of knowledge, as we have a lot of experience of recycling. We could increase motivation by presenting information and explaining why collecting and recycling materials is so very important. There is merit in approaching everyone from affiliated customers to politicians and school children to explain how El-Kretsen works, as this would increase the public’s awareness of the systems and processes we have spent the past 20 years building up. It would be a way of inviting relevant questions and raise support for our continued development.

Another possibility is alternative handling of the materials collected. There are many research projects currently looking into how different methods such as reuse or refined recycling processes could be made to serve the environment even better.

Statistics

What we recycle

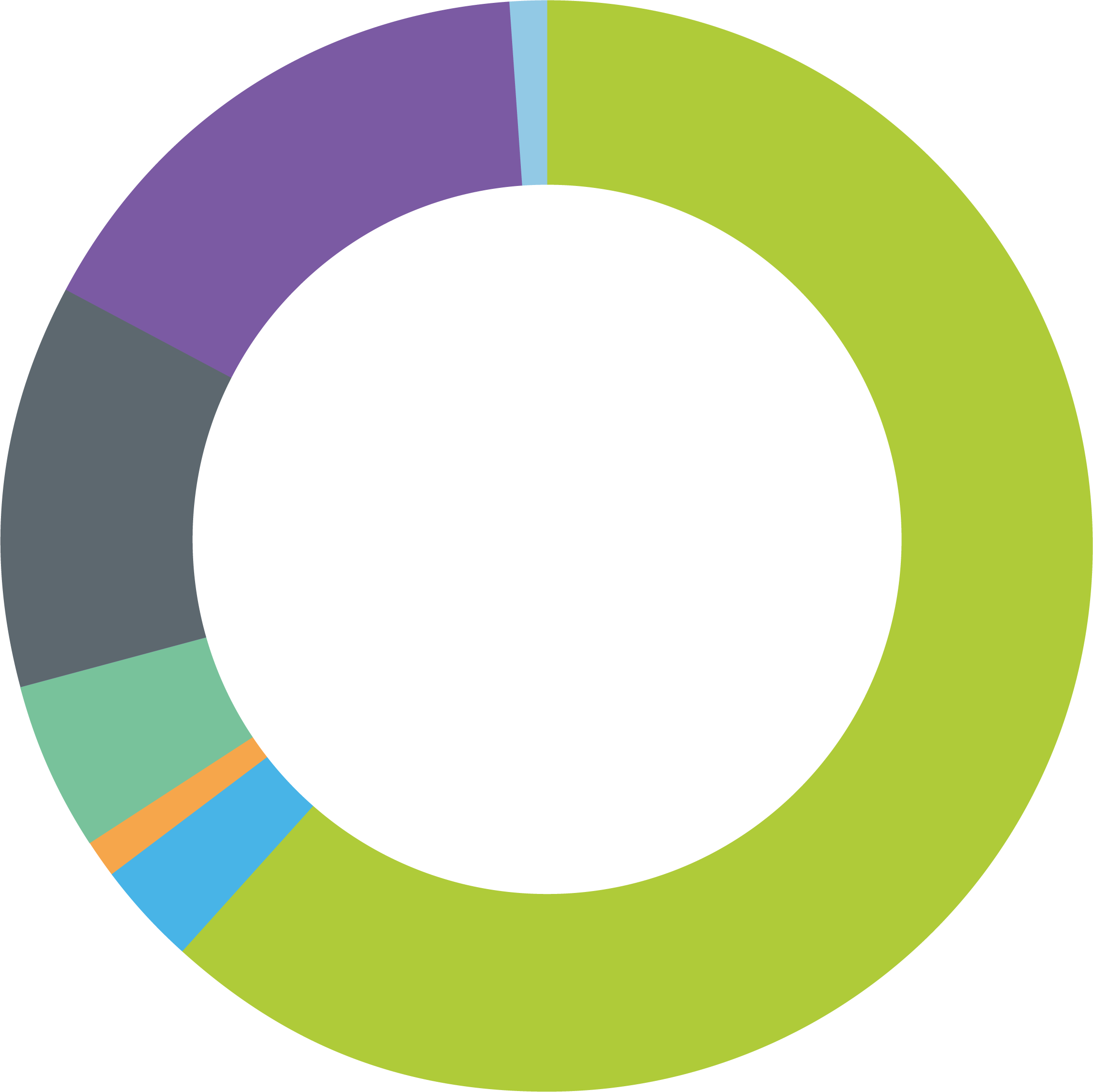

The items we collect are sorted, dismantled and fragmented in order to produce the purest material flows possible.

Collected in total

In 2020, the total collection of electrical and electronic products and batteries amounted to 156 thousand tonnes which corresponds to approximately 15 kilos per person and is an increase by 5.5 per cent since 2019. The collection covers six fractions: Small appliances; Refrigerators and freezers; White goods; Batteries; Fluorescent lamps (compact and straight); LED and incandescent light bulbs. We also deal with the WEEE that ends up in the municipal recycling bins despite being professional products.

Collected (in comparison)

The amounts collected and treated are reported to the Swedish EPA in six separate categories. The table below shows a comparison for the last three years.

| Collected (weight in tonnes) | 2019 | 2020 |

|---|---|---|

| Small appliances | 80 225 | 84 512 |

| Refrigerators and freezers | 24 662 | 28 120 |

| White goods | 35 805 | 36 017 |

| Batteries | 3 383 | 3 460 |

| Flourescent lamps (compact and straight) | 1 878 | 1 813 |

| LED and incandescent light bulbs | 624 | 616 |

| Other/professional electronics | 1 030 | 1 183 |

| Total | 147 627 | 155 721 |

Material content per fraction

Here we report what different fractions contain and how their materials are treated.

| Material | Processing | % |

|---|---|---|

| Iron | Material recycling | 40% |

| Copper | Material recycling | 5% |

| Aluminium | Material recycling | 4% |

| Plastic | Material recycling | 18% |

| Silver | Material recycling | 0,012% |

| Gold | Material recycling | 0,001% |

| Palladium | Material recycling | 0,0005% |

| Other metals | Material recycling | 10% |

| Other combustible materials | Other recycling | 10% |

| Not recyclable or combustible material | Landfill | 13% |

| Total | 100% |

| Material | Processing | % |

|---|---|---|

| Iron | Material recycling | 21% |

| Aluminium | Material recycling | 2% |

| Copper | Material recycling | 2% |

| Other metals | Material recycling | 9% |

| Plastic | Material recycling | 16% |

| Glass | Other recycling | 42% |

| Other combustible materials | Other recycling | 8% |

| Not recyclable or combustible material | Landfill | 1% |

| Total | 100% |

| Material | Processing | % |

|---|---|---|

| Iron | Material recycling | 23,2% |

| Zinc | Material recyling | 21,2% |

| Lead | Material recycling | 3,7% |

| Nickel | Material recycling | 3,1% |

| Cadmium | Material recycling | 1,9% |

| Lithium | Material recycling | 0,6% |

| Other metals | Material recycling | 0,3% |

| Cobolt | Material recycling | 0,3% |

| Aluminium | Material recycling | 0,2% |

| Other combustible materials | Other recycling | 13,6% |

| Not recyclable or combustible material | Landfill | 31,9% |

| Total | 100% |

| Material | Processing | % |

|---|---|---|

| Aluminium and other metals | Material recycling | 17% |

| Glass | Other recycling | 79% |

| Plastic | Other recyling | 0,1% |

| Other combustible materials | Other recycling | 1% |

| Not recyclable or combustible material | Landfill | 3% |

| Total | 100% |

| Material | Processing | % |

|---|---|---|

| Iron | Material recycling | 62% |

| Aluminium | Material recycling | 3% |

| Copper | Material recycling | 1% |

| Other metals | Material recycling | 5% |

| Plastic | Material recycling | 0,2% |

| Other recyclable materials (concrete, etc.) | Material recycling | 12% |

| Other combustible materials | Other recycling | 16% |

| Not recyclable or combustible material | Landfill | 1% |

| Total | 100% |

| Material | Processing | % |

|---|---|---|

| Iron | Material recycling | 67% |

| Aluminium | Material recycling | 3% |

| Copper | Material recycling | 2% |

| Other metals | Material recycling | 2% |

| Plastic | Material recycling | 13% |

| Glass | Material recycling | 1% |

| Other combustible materials | Other recycling | 11% |

| Not recyclable or combustible material | Landfill | 2% |

| Total | 100% |

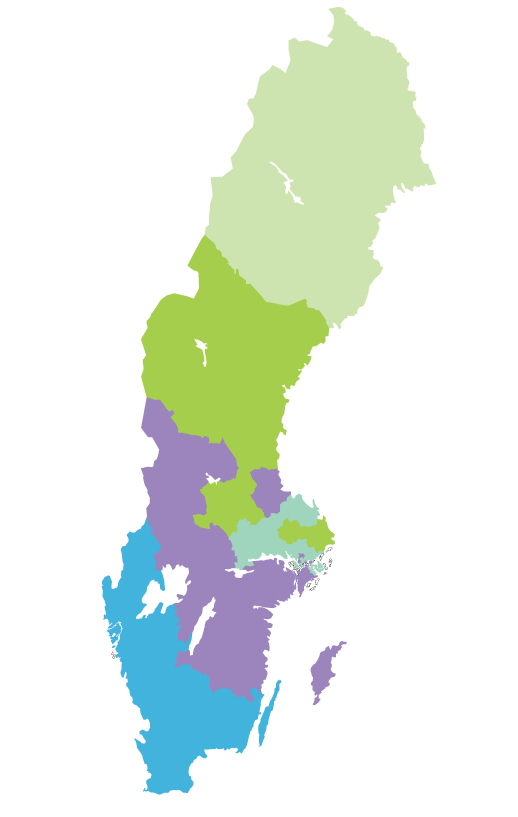

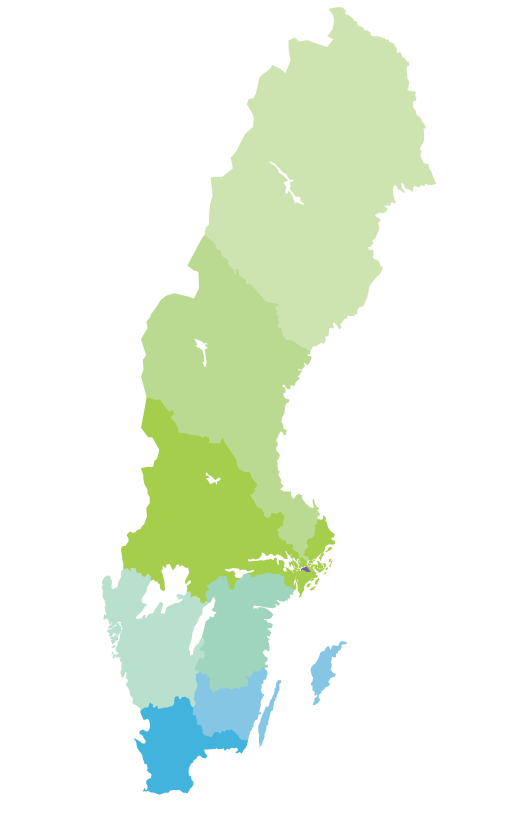

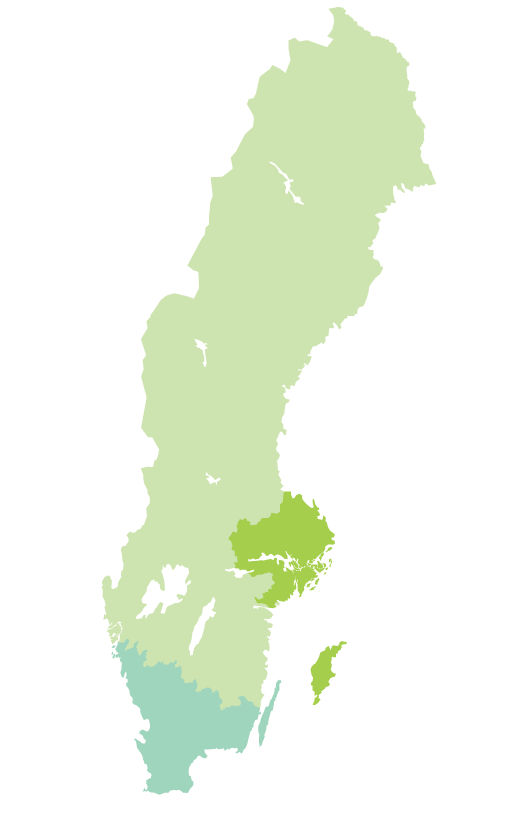

Catchment areas

Recycling collection is divided into six fractions. The maps below indicate where the items collected in each fraction are handled and by which partner. When describing the collection process, the most straight-forward category is luminaires, which all go to the same place regardless of where in Sweden they are collected. Some products, like white goods, are handled in several different locations while products such as refrigerators and batteries require more closed and specialized processes. Consequently, the latter are only handled in one or a few locations.

- Kuusakoski: Skellefteå

- Kuusakoski: Timrå

- SIMS: Katrineholm

- Stena Rosersberg

- Stena Halmstad

- Kuusakoski: Skelleftehamn

- Kuusakoski: Gävle

- Rang-Sells: Västerås

- Svensk Freonåtervinning: Hässelby

- Lantz Järn&Metall: Norrköping

- Skrotfrag: Göteborg

- Skrotfrag: Oskarshamn

- Stena Recycling: Malmö

- Revac: Hova

- Svensk Freonåtervinning: Hässelby

- Stena Recycling: Halmstad

- Renova: Göteborg

- Stentorps Service

- Stena Halmstad

Recycling targets

Sweden’s targets for the recycling of WEEE and batteries are regulated by SFS 2014:1078 and SFS 2008:834. In its capacity as a collection system, El-Kretsen handles the majority of Sweden’s household WEEE. However, our waste contractors can also collect and treat consumer electronics independently. If they collect, say, end-of-life computers at a school or a hospital, these will fall under the category “consumer electronics” despite the fact that they have been used in an organisation or in a business context. As our subcontractors report the WEEE they collect separately to us, it is included in our statistics. Consumer WEEE collected by other contractors, however, is not included in our statistics.

There are no consolidated statistics for the second-hand market in Sweden or for Swedish reuse habits. In order to identify and assess any discrepancies between the EEE put on the Swedish market and the WEEE collected, we use parameters such as “amounts sold”, “average lifespan” and “waste collected”. However, seeing any clear trends is difficult as Europe is an open market and many other countries have a more active second-hand market than we do in Sweden. We simply cannot tell how much of what is put on the Swedish market later disappears out of the country. Having a clearer picture of this would make it easier to produce more accurate statistics of the amounts collected and treated in Sweden. In addition to gathering statistics on reuse, El-Kretsen runs projects with the aim of advancing along the path to a circular economy through the reuse of entire products or parts of products.

Our research into the age of the WEEE we collect shows that the majority of products has a median lifespan of 10-20 years. In combination with new shifts in technology, this longevity may result in misleading statistics when comparing the weight sold and the weight collected in the same year. In order to achieve more precise collection statistics, our analytical plant has for several years now also been collecting data relating to lifespan and numbers.

All statistics broken down by municipality can be found digitally here, where you can also compare all individual municipalities with the national average. Or download the entire table as a pdf below: